- Flex PCB Blog

- PCB Assembly Blog

- FPC Research Blog

- Preparation of FPC based on ultrasonic spraying method_4_Experimental Results

- Preparation of FPC based on ultrasonic spraying method_3_Experimental Procedure

- Preparation of FPC based on ultrasonic spraying method_2_Experimental Platform and Principle

- Preparation of FPC based on ultrasonic spraying method_1_abstract

- Research on Layout Design Method of Ultra-thin FPC_4_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_3_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_2_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_1_introduction

- Research progress on polyimide FPC_2_the field of FPC

- Research progress on polyimide FPC_1_Introduction

- Analysis of Vibration Characteristics of FPCBs _4_Summary

- Analysis of Vibration Characteristics of FPCBs _3_Finite Element Analysis

- Analysis of Vibration Characteristics of FPCBs _2_Theory of Vibration Analysis

- Analysis of Vibration Characteristics of FPCBs Under Random Vibration_1_Introduction

- Design Methods for FPCBs_5_Practical Application

- Design Methods for FPCBs_4_Electrical Circuit Design and Examples

- Design Methods for FPCBs_3_Structure Design Method and Examples

- Design Methods for FPCBs_2_Component Selection Methodology and Examples.

- Research on Design Methods for FPCBs

- Application of MPW technique for FPCBs _4_Summary

- Application of MPW technique for FPCBs_3_Experimental results

- Application of MPW technique for FPCBs_2_Experimental setup

- Application of MPW technique for FPCBs_1_Principle of MPW

- Application of FPCB in PC motherboards_4_ Results and discussion

- Application of FPCB in PC motherboards_3_ Numerical analysis

- Application of FPCB in PC_2_ Experimentation

- Application of FPCB in PC motherboards

- A Bus Planning Algorithm for FPC Design _4_Experimental result

- A Bus Planning Algorithm for FPC Design _3_Proposed Algorithm

- A Bus Planning Algorithm for FPC Design _2_Preliminaries

- A Bus Planning Algorithm for FPC Design _1_Introduction

Preparation of FPC based on ultrasonic spraying method_3_Experimental Procedure

2.1 Experimental Procedure

Nano silver conductive ink is used as a spraying material due to its low sintering temperature and good conductivity [10-11]. The solution chosen is the PG 007 series product from South Korean company PARU, which has a silver content of 70% (mass fraction), viscosity of 2,000 mPa·s, and surface tension of 53 mN/m. To ensure good uniformity of the coating, the experiment did not directly use the nano silver solution for spraying. Instead, it was diluted with anhydrous ethanol in a volume ratio of 1:5. The diluted nano silver solution has a lower viscosity, which is beneficial for improving the atomization effect. Since anhydrous ethanol has strong volatility, it will quickly evaporate during the experimental process without adhering to the surface, resulting in a very thin nano silver coating on the PI film, thus meeting the printing requirements of different thicknesses.

After repeated experiments and comparisons, it was found that adjusting the heating platform to around 60 °C can help the printed circuit to dry quickly in the area after the nozzle passes by, effectively preventing liquid leakage. The feed rate of the solution also affects the atomization effect. When the feed rate is too low, it leads to insufficient liquid supply, and the nozzle atomization becomes intermittent. When the feed rate exceeds a certain value, the transducer may not have enough time to atomize, causing the liquid to drip. In addition, the power adjustment of the ultrasonic generator also needs to be synchronized to select the optimal state suitable for the current liquid atomization. After a series of adjustments, the best atomization effect was achieved at a feed rate of 0.15 mL/min and a power of 1 W. The atomized droplets move under the guidance of compressed gas. Observation and comparison showed that when the air pressure is around 6 kPa, the droplet distribution is most uniform.

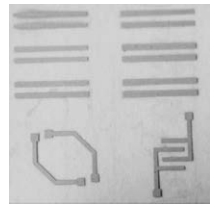

Experiments were conducted according to the parameters obtained above, and the sintered nano silver particles appeared white (see Figure 4). Figure 5 shows the bending state of the printed circuit, indicating that the required circuit pattern was successfully attached to the PI film, and it possesses good flexibility, continuity, and uniformity. Even after multiple bending tests, it can maintain its original shape, and the corners and edges of the circuit can also exhibit their proper shapes. The sintered PI film was measured for sheet resistance (using a four-probe resistivity meter), and its microstructure and surface morphology were characterized using an EMPYREAN type X-ray diffractometer (XRD) and a MERLIN Compact type scanning electron microscope (SEM).